LIQUID / LIQUID DUTIES

High turbulences and strong mechanical capacity

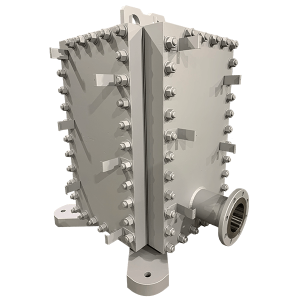

Robust and patented

Robustness , reliability for welded block heat exchanger is the key point. Nexson has patented his own welded block heat exchanger, named GreenBox ™. With proven pressure and temperature cycling tests, this type of heat exchanger is one step ahead the competition in terms of robustness.

2 semi-fouling medias

This welded heat exchanger is designed to handle one or two semi fouling medias at the same time. Fouling handling is done thanks to corrugated plates which offer high shear stress values on the wall surface

Easy to clean

Thanks to demountable panels,the welded heat exchanger is easy to clean with hydro pressure water jet.

Interchangeable “heart” / Heat transfert area

Thanks to its modular construction, we can take out the heat transfer area from panel, get a new one and keep the existing panel.

In case of raw material changing requirement due to process evolution a long term operation approach is possible for this heat exchanger technology

Close temperature approach

Thanks to the corrugated plates , combined with high K value, you can reach a very close temperature approach and even get a crossing temperature

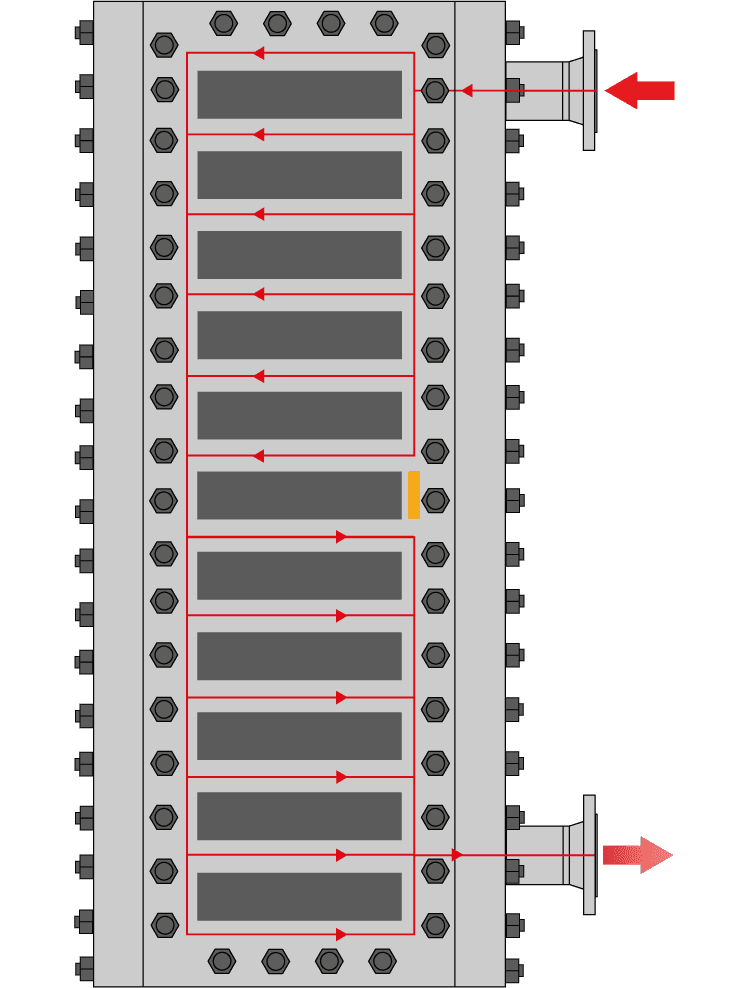

High volume flow with limited pressure drops

Green box welded heat exchanger is a multiple cross section heat exchanger which allows a different baffles arrangement according to the duty and pressure drop limitation required

Full inspection of the heat transfer area

By taking away the 4 panels you can access the whole heat transfer area for inspection during annual plant shutdown.

Traditionally used as

- Heat recovery / Interchanger

- Heater

- Cooler

Associated products

AVAILABLE MATERIALS

- Stainless Steel

304L / 1.4301

316L / 1.4404

- Stainless steel / Nickel based alloys

254SMO / 1.4547

C276

Nickel 200/201 904L / 1.4539 Alloy 59

- Titanium

Titanium Gr1

Titanium Gr11