Spiral steam heater type 3

Steam heater

Able to work in extreme conditions (of pressure and temperature), this single channel heat exchanger, with self-cleaning effect, has become the alternative to the shell & tube exchangers. More compact and until 3 times more thermally efficient, the Spiral Plate Heat Exchanger gives the possibility to do substantial savings in installation, operation and maintenance.

This SPHE model 3 can be used as steam heater for tough duties. Fouling duty channel enables easy access for inspection or for an eventual mechanical cleaning

Spiral heat exchanger is made to handle cycling duties, thanks to its robust construction. Nexson spiral heat exchanger can expand without mechanical failure during the pressure or temperature increase. That’s why the spiral heat exchanger is used as a steam heater.

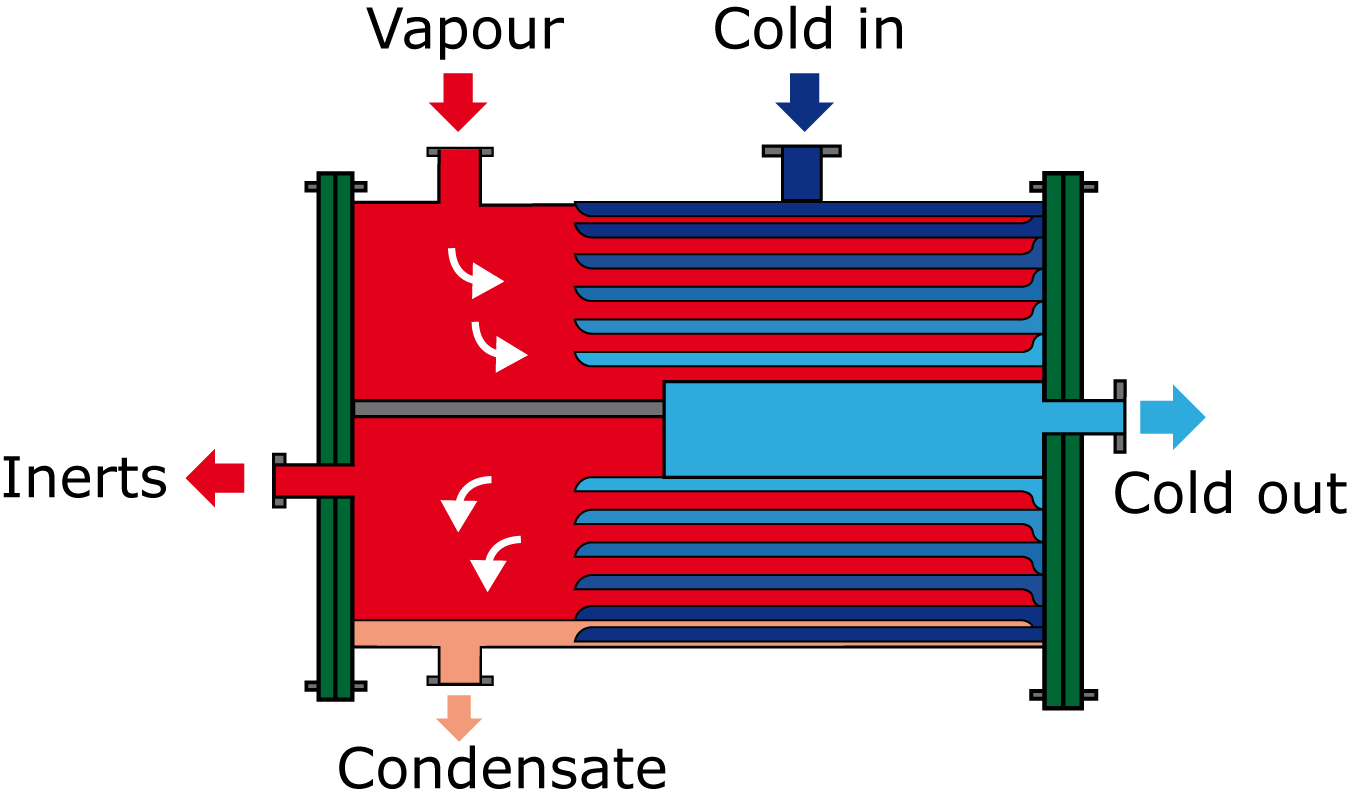

Condensation

The vapor circulates, cross flow, in an alternated channel, with negligible pressure drop and the coolant circulates in an accessible spiral channel.

Negligible pressure drop

Thanks to the cross flow feature on the steam / vapour side there is nearly no pressure drop.

Low maintenance cost

Nexson spiral heat exchangers are designed to maximize heat transfer surface. They can be set up vertically or horizontally with no need for complex installation. In addition maintenance costs are very limited.

Heat transfer area surface

Heat transfer area available from 2 to 500m².