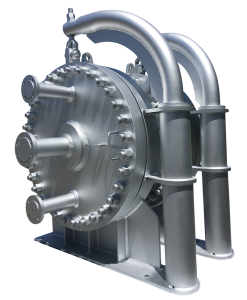

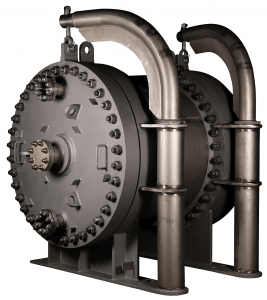

For liquid duties & high pressures / temperatures – Type 1

Thanks to its specific design, the liquid to liquid heat exchanger can handle one or two fouling fluids. Both channels are easy to access for inspection and cleaning. Your alternative to the shell and tube heat exchangers !

This SPHE model is specifically designed to handle up to 200 barg / 450°C for tough applications.

Energy saving

The spiral design and optimization of conditions in both channels of the Nexson spiral heat exchangers provide a high heat transfer value (K value) which leads to big savings in energy costs.

Low maintenance cost

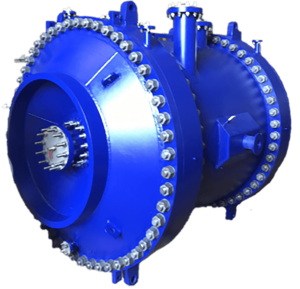

Nexson spiral heat exchangers are designed to maximize heat transfer surface. They can be set up vertically or horizontally with no need for complex installation. In addition maintenance costs are very limited.

Compact size and robustness

Regarding the liquid to liquid duty, one Nexson spiral heat exchanger can replace 3 traditional Shell & tubes products, releasing footprint for the process part.

Self cleaning effect

Thanks to the single channel configuration, a turbulent flow is created to handle tough medias. Since it is a single channel heat exchanger, if there is any cross section reduction inside the channel, flow velocity will increase flushing out the deposit.

No dead zones in the channels

Thanks to its defined cross section uniform from the beginning to the end of the spiral core combined with turbulent flow, the spiral heat exchanger technology is considered as a no dead zone heat exchanger in the channel flow.

Customized

Nexson high pressure design spiral heat exchangers are customized to your need. From 60 barg in standard up to 200 barg for special application , the sales team is available to answer your request.

Full access to heat transfer area

Access and inspection of the whole heat transfer surface is facilitated thanks to openable end covers.

Fouling / Erosive / Corrosive medias

Nexson spiral heat exchangers are designed to handle suspended fibers / particles in the media. When it comes to erosive and / or corrosive medias, we propose some adapted features to handle it.

Temperature approach

Nexson spiral heat exchangers provide the possibility of medias temperatures approach around 3°C.

Heat transfer area surface

The heat transfer area available for a liquid to liquid exchanger fluctuates from 2 to 700m².

Traditionally used as

- Heat recovery

- Heater

- Cooler