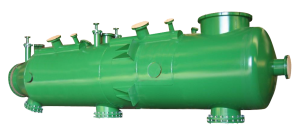

2 phases spiral column – Type 2 column

Condensation

The vapor circulates, cross flow, in a fully opened channel, with negligible pressure drop and the coolant circulates in a closed spiral channel.

The column is made of several spiral heat exchanger welded in series in the same shell to achieve large condensing duties.

It is perfectly suitable for vacuum condensation with negligible pressure drop.

Evaporation

The fluid to evaporate circulates in an adjusted channel gap, fully opened, that allows working with fouling fluids. it also enables easy access for an inspection or an eventual mechanical cleaning.

Negligible pressure drop

Thanks to the cross flow on the steam / vapour side there is nearly no pressure drop (we are in a range of 0.1 kpa)

Condensation under vacuum

The very low pressure drop allows spiral heat exchangers to process under complete vacuum conditions.

Low maintenance cost

Nexson spiral column heat exchangers are designed to maximize heat transfer surface. In addition, we supply our equipement with inner cleaning system to keep maintenance costs limited.

Customized to fit your need

Nexson spiral colum heat exchangers are customized to fit the process need and existing plant arrangement.

Heat transfer area surface

The heat transfer area available for this spiral column heat exchanger varies from 200 to 5000m².