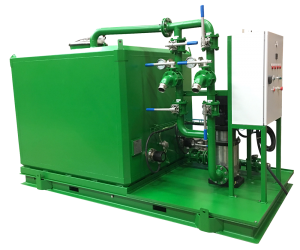

Clean in place (CIP module)

Clean In Place (CIP module) facilitates the cleaning of your installation and is easy to move from one place to the other

How Nexson Group can facilitate the cleaning of your installation whatever the type of exchanger used and help you preserve the thermal characteristics of your heat exchanger

Nexson Group is YOUR supplier for a large range of clean in place (CIP) units suitable for all types of heat exchangers enabling :

- To keep your process loop always clean

- To less expose your workers to chemicals

- To maintain plant capacity / process availability

- To save time

Connect the CIP skid hoses to drains & vents connections, run the CIP process, disconnect the CIP unit. The heat exchanger is back to full performance capacity again

These CIP skids are also used for process equipment cleaning such as tanks, piping, pumping systems, …

TECHNICAL FEATURES

- This CIP range single pass processing is built up with an integrated tank to collect waste liquid during recirculation flow which is water saving.

- The inner tank is equipped with filter basket to avoid to pollute the cleaning already done. All parts internal and external are in 316 / 316L stainless steel.

- Detergent cleaning is made at a flow velocity from 1.5 to 2.4 m/s which improves cleaning efficiency. Detergent temperature can be adjusted up to 70°C

- Much higher effective cleaning compared to manual cleaning.

- Detergent flow rates can be way reversed directly on the skid thanks to the direction valves.

We provide suitable chemical clean in place Modules (CIP) equipped, in standard, with all simple and efficient systems.

Nexson Group CIP Module is a transportable skid containing all equipments : tank, pump, regulation, heating system… ready for use.

Range : from CIP 200 liters to CIP 3000 liters

Full options for special applications are available on request.

BENEFITS

- Minimized cleaning time: faster & more efficient cleaning than manual processing

- No disassembly / reassembly

- Water & detergent flow optimization

- Less chemical exposure for workers

- Detergent efficiency improved with a temperature control system up to 70°C

- Possibility of cleaning dead zones

- Tank storage for waste issued from cleaning

- Maintain plant capacity / process availability

- Pressure / Flowrate directly monitored by the skid